Custom's Space Saver Series

Custom’s Space Saver radiators are built from copper and brass, the best radiator cooling material available, now and in the foreseeable future. Custom’s use of commercial cores, utilizing staggered tubes and louvered fins in their Street Rod Radiators, are responsible for CAR earning a reputation for superior cooling and dependability.

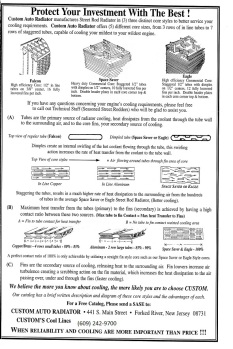

Space Saver cores are made with seamless welded tubes for additional strength and leak prevention. These tubes are designed for optimum coolant flow in limited space. (Tubes are the primary source of cooling, heat dissipates from the coolant through the tube wall to the surrounding air as well as the core fins). One of the advantages in utilizing a straight fin design is that you can stagger the rows of tubes.

The Space Saver’s staggered tube pattern provides superior air dynamics around the tube. The tube to air heat transfer rate is significantly increased simply by staggering the rows of tubes. The cooling advantages are so obvious that you may wonder why everybody doesn’t use staggered tubes. Staggered tube cores are more expensive and much more efficient at transferring heat.

Staggering the tubes, results in a much higher rate of heat dissipation to the surrounding air from the hundreds of tubes in the average Space Saver Street Rod Radiator, (Better Cooling).

The Space Saver core is made from straight fins. (Fins are the secondary source of cooling, releasing heat to the air passing through the core area). A Space Saver core has 10 fins per inch, with thousands of louvers per fin, approximately 50,000 louvers per core. Fin louvers increase air turbulence through the core, creating a scrubbing action on the fin material which increases the heat dissipation to the air passing over, under and through the fins (Faster Cooling). Space Saver fins are computer designed and manufactured to precise specifications to insure maximum cooling efficiency and strength.

One of the straight fin core design advantages, over conventional cores, is that it does not rely on the fin to the solder bond. The space saver tubes are manually inserted in the fin opening using a tube sword, this method mechanically locks the tubes in place at each fin intersection, prior to the solder bonding of approximately 40,000 tube fin connections. This interlocking of fin and tube prior to soldering is a much more labor intense, time consuming process. The Space Saver cores additional cost to manufacture is justified by the superior strength and faster heat transfer rate achieved by using this commercial bonding technique.

Another Space Saver advantage is that its tubes (your primary heat source) are in full contact (interlocked) with your fins (your secondary heat source). The primary and secondary sources have 100% mechanical contact. No dead spots. This perfect ratio is not achievable with any other style of core other than straight fin, and is way ahead of our competitors 80 to 90% tube to fin contact ratio. Space Saver radiators are a CUSTOM AUTO RADIATOR exclusive!

Max Tube To Fin Contact = Max Heat Transfer To Fins

Copper/Brass - 4 rows small tubes 80% - 85%

Space Saver & Eagle 100%

Aluminum - 2 row large tubes 85% - 90%